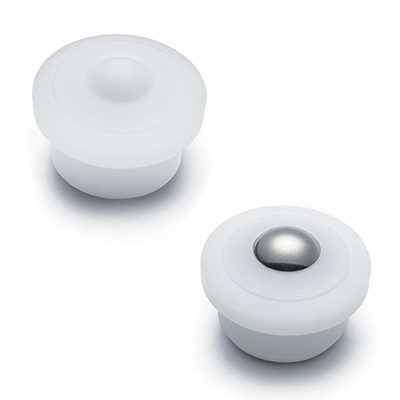

UTB-P - UTB-SST

Transfer units

Body in acetal-based technopolymer, white colour.

Internal support and transfer balls of the main ball in AISI 316 stainless steel.

Standard executions

- UTB-P: main ball in acetal-based technopolymer (POM), white colour.

- UTB-SST: main ball in AISI 316 stainless steel.

UTB ball transfer units are particularly suitable for applications on transfer and conveyor lines or end of production lines.

They facilitate both linear and rotational movements favouring maximum smoothness (see Technical Data).

The self-lubricating technopolymer structure ensures maximum cleanliness as it does not require lubrication with oils and greases.

The technopolymer ball lends itself to handling loads with delicate surfaces.

The stainless steel ball lends itself to handling loads with sharp and angular surfaces.

Furthermore, since these are corrosion-resistant materials, it is possible to wash them, even frequently.

GN 509.3:spring rings in stainless steel to allow easy, quick insertion and removal of UTB units.